I wanted to write and let you know that you may want to visit the new blog over at http://www.c.Optmzr.co

Although Blogger helped me prove a point to a co-worker, it doesn't have the depth and sophistication to support multiple authors and a richer long term experience. As such, I invite you to cruise over there and check it out.

I'm not going to "kill" this blog, but my contributions will be less often here. Over there, we hope to post multiple times per week and create a rich environment for others to contribute as well.

Cheers! and thanks for reading!

Wednesday, December 18, 2013

Wednesday, December 4, 2013

Indiana's Conservation Consulting Initiative

Indiana farmers lead agriculture in so many fascinating ways... notill, precision ag and cover crops. Certainly other states in the US have massive acreage of each of these but it appears to me that Indiana has an amazing foundation for these practices to gain deeper and wider adoption faster.

First, Indiana has good but not great soil and weather. I joked with several Illinois and Iowa customers this summer, that Indiana would fare well with the extra rainfall... we have small valleys! Between these small valley's we have lots of clay, timber soils as well as sands, depending on the area of the state. Rolling terrain increases erosion but also sparks creativity around reduced tillage and cover crops.

While this terrain varies, we are also fortunate to receive ample rainfall. Different than some of our western counterparts or even far eastern farmer friends, we tend to get ample rainfall to capitalize on soil health management. (I would argue that the more severe the climate the more response you get from soil health management but that's another topic.) Anyways, rain makes grain and thus, well managed clays can quietly yield 200+ bushels per acre and cost far less to purchase or rent, again accelerating creativity.

Finally, this variability, yield potential and field size, afford the Indiana farmer technology investments and experimentation that outpaces other areas with less variability and scale. No doubt, an Illinois or Iowa farmer can achieve massive scale, but the variability within their fields has struggled to justify the on-farm experimentation behind precision ag thinking.

This all adds up to some exciting people making a real difference around the globe. I'm proud that Advanced Ag Solutions is among the approved mentors for CCSI. http://ccsin.iaswcd.org/

Next week we share some of what we've learned with the "hub farmers" who are doing on-farm research around the state. I'm sure they'll have some great roundtable discussions!

First, Indiana has good but not great soil and weather. I joked with several Illinois and Iowa customers this summer, that Indiana would fare well with the extra rainfall... we have small valleys! Between these small valley's we have lots of clay, timber soils as well as sands, depending on the area of the state. Rolling terrain increases erosion but also sparks creativity around reduced tillage and cover crops.

While this terrain varies, we are also fortunate to receive ample rainfall. Different than some of our western counterparts or even far eastern farmer friends, we tend to get ample rainfall to capitalize on soil health management. (I would argue that the more severe the climate the more response you get from soil health management but that's another topic.) Anyways, rain makes grain and thus, well managed clays can quietly yield 200+ bushels per acre and cost far less to purchase or rent, again accelerating creativity.

Finally, this variability, yield potential and field size, afford the Indiana farmer technology investments and experimentation that outpaces other areas with less variability and scale. No doubt, an Illinois or Iowa farmer can achieve massive scale, but the variability within their fields has struggled to justify the on-farm experimentation behind precision ag thinking.

This all adds up to some exciting people making a real difference around the globe. I'm proud that Advanced Ag Solutions is among the approved mentors for CCSI. http://ccsin.iaswcd.org/

Next week we share some of what we've learned with the "hub farmers" who are doing on-farm research around the state. I'm sure they'll have some great roundtable discussions!

Friday, November 1, 2013

Audio Interview about Optimizer 2.0

A former college intern stopped by the office this morning to interview me for his sales class. He asked if he could record it. I said sure. After he left, I happened to think "that'd be fun to publish." So, here it is!

Listen Now

WARNING: This is long and non-edited. I think most of it is PG-13 but my apologies to anyone I may have offended.

Listen Now

WARNING: This is long and non-edited. I think most of it is PG-13 but my apologies to anyone I may have offended.

Wednesday, July 31, 2013

Everyone Wants One Device

At a recent dinner meeting a CEO of a prominent company was saying how everyone wants a single software package that consolidates

all their activities. He said this is true in agriculture the same as it is other places. He told a

story of carrying a PDA and phone and how he wished they were one in the

same. I remember those days and thoughts

myself quite clearly. Everyone told me I

was crazy... first for carrying the Palm Pilot and secondly for thinking people

would like such a combined device.

Ironically, it was pointed out that he was carrying two

smartphones now... or should I say, had two smartphones sitting on the dining

table of the restaurant. He laughed and

went on to talk about tablets and laptops and how at one point he had so many

devices he couldn't fit them in a single briefcase.

I didn't want to write a blog post about devices

however. What I wanted to reflect on was

the desire of people to use technology to consolidate, streamline and simplify

their lives. This is a noble ideal,

however, almost every disruptive technological wave is wrought with desire to do something that was either a) not capable before or b) totally new way of doing what was done before. Example... now that you've got a wireless connection on your PDA, what type

of programs can you build now? It's

revolutionary stuff.

Combining devices or software is a bode to creative

intellect and ambitious visionaries. The

trouble with this however is the new device or software is much like the main

character in a Shakespearean tragedy. He

suffers from an undeniable ending...

whereby that which defines you, destroys you. In some modern movies the same rings

true. We love these stories because we

see it coming but can't stop it. It

relates to our lives in a very personal and frightening way.

In precision ag and modern farming I often hear requests

for a single display in the tractor cab.

Or, perhaps a single software that would manage both their financials,

their grain marketing and their variable rate precision ag files. There have been a few programs that strived

relentlessly to obtain this nirvana.

However, they just never quite have "enough" features... and

ultimately the feature creep in trying to obtain this vision ultimately kills them.

Instead of bemoaning the

hopelessness of our state, I believe we can learn from other

industries. How is it that Google, Apple

and Microsoft can all share calendar apps and yet compete with each other? They use API's issued by their

competitors. The original goliath builds

an API so that smaller innovators can build on their foundational

technology. But in so doing, they open

up gates to giant competitors in other industry segments. Why

would they do this? Because it is

ultimately in their best interest to do what they do best and provide

opportunity for customers to start swimming in their pool, regardless of what

device or software platform is currently the customer's favorite.

For precision ag to "go mainstream" at the farm

level, we need both goliaths and startups cross-referencing each other's

API's. In so doing farmers themeselves

can stitch together systems that work well for themselves and access the best

features of each... and do so fairly easily. Sure there will always be problems to solve but this simply creates opportunities for new

innovators to step in and fill those new gaps.

Who is in the best position to promote this culture? Software purist companies. They have no incentive to move product

through their software, but instead must move their software for the sake of

the software's value in and of itself.

With that said, it probably is NOT going to be a software company that

aimed at being all inclusive themselves.

I'm personally on the look out for software companies that want to do one thing

really, exceptionally well and are open to playing well with others. Those fine companies will reach more users

faster, and deliver greater value propositions versus their price.

Here is another way to think about this "one device" desire... we already have just one device! Our own brain and body. We stitch together various technology and hardware to accomplish our goals at the appropriate value. I urge you to look for components that talk to others as a core requirement.

Here is another way to think about this "one device" desire... we already have just one device! Our own brain and body. We stitch together various technology and hardware to accomplish our goals at the appropriate value. I urge you to look for components that talk to others as a core requirement.

Tuesday, July 9, 2013

Ultra High Yield Soybeans

I've written a lot about precision management of corn lately, so I figured I'd give soybeans a nod of the hand. Here are the building blocks to insanely high soybean yields.

1. Start with good soil. If you haven't got any then improve it.

2. Rotate with other crops. Multiple years of corn, then cereal rye cover crop.

3. Plant early. Yield potential is established AFTER you plant and you need flowering sites.

4. Time fertility for ~20# soil nitrates prior to V3. This can be from variety of sources... no more, no less.

4. Plant very long season variety. Again, more flowering sites increase max potential.

5. Adjust population to expected lodging and shade. Tall beans never yield.

A) Lower populations where soil nitrogen is expected to be higher than desired early.

B) Lower populations in wider rows for less plant to plant competition.

C) Lower populations with longer maturity (they'll make it up)

6. No weeds allowed. Spray early and often.

6. Track soil moisture and only augment late if possible. No irrigation? Pray for rain.

7. If you have soil moisture late, top dress with N at beginning of seed fill to meet yield goals.

8. Treat pests and disease according to scouting.

9. Consider desiccant for harvest aid.

10. Harvest timely and with proper settings.

11. Sow cover crop to soak extra high N load from vibrant plants.

This is over simplified and highly opinionated. It's also proven with experience on about a zillion field observations and various trials. I left out some things that should be obvious, and also some details about things that will make this all automatic. We're working on software that will help. In the mean time, this should guide you.

The key to high yielding soybeans is having an environment that is rich for the plant's needs at each time of its life cycle. There are two primary stages. Vegetative and Reproductive. They overlap from flowering until the end of new leaf development. You want to maximize the nodes and thus flowering sites per acre based on your environment. This changes across the field and throughout your planting window. You need to adjust according to these things! Furthermore, you should augment your available nitrates to stimulate bacteria to get to work early (a little N boosts leaf surface and juices the roots for faster and greater nodulation.) But, you don't want too much N early as the bacteria get lazy. This might mean reducing your tillage and growing a high C:N cover to soak and tie up N early. Sounds funny to suggest augmenting N levels to DECREASE nitrogen levels but it's truly important. In fact, studies show too much N early can delay N fixing and ultimately crush yields. Be careful.

Once healthy, evenly spaced plants have taken off in a nitrogen balanced environment, your job is to protect them so they can develop an insanely high number of flowering sites. This means protecting their water source (soil), root development (compaction), and leaf surface (insect and disease.) With crop rotation most of that is taken care of free of charge. The planter becomes increasingly valuable as your populations become lower. You cannot skimp here. Try treating them with same affection as corn... seriously, try it. Some people are known to time their row units so they drop equally spaced soybean seeds... and raise 160+ bpa records.

Ultra long season varieties have longer vegetative periods. In fact, we have proven that the day length sensitive talk is bogus. That's right... it's garbage. Instead, focus on GDD heat units prior to flowering. After flowering the soybean marches to maturity based on the fact that there is a night and not necessarily the length of the night (can anyone say, street lamp green beans?) So, the plant sees the light switch, takes a nap and then wakes up to grab sunlight again. You should focus on selecting a variety that will march to maturity close to or even after anticipated frost given your planting date and temperature outlook. (obviously, you don't want to harvest every field after frost, but this post is talking about ultra high yield, okay!)

Soybeans grow like a cube. Their geometry is much different than corn (a cylinder). They will canopy at about the same height as their row width. This isn't exact but it's a decent rule of thumb. Given their ability to add flowering sites at an exponential rate, your exact population is highly influenced by your row width, planting date and maturity. What is the best row width? Tell me your planting date, seed variety and soil properties and I'll have an opinion.

As your tree-like soybeans sprawl out with tons of flowers and massive nodules on their roots, you'll want to know what your soil moisture profile looks like late in the season. You should have well over 100 bushel potential based on node count per plant. As such, you'll need to feed the seeds developing in all these pods! History shows that good bean years favor dry early and wet late with good soil N mineralization happening late. Soybeans require around 5# per bushel of N and can produce 60-70% from atmosphere. This means that if your soil contributes 80# (3.5% OM soil) your cover crop releases some late and you want more than 100 bpa, you're going to need an additional 50-80# N top dressed. How do you apply it and what source? That's up to you but do as little crop damage as possible and get it into the root profile. Foliars are not going to be enough.

For most of my midwest farmer buddies, the idea of spraying soybeans in October with a descecant sounds crazy. I might get made fun of... but this won't be the last. The truth is, a crazy lush, full season soybean plant is going to want to hang on and keep pumping late into the fall. It really doesn't care that you have empty grain bins. It wants more and more seed and will push the plant right up until you or mother nature say stop. That's totally okay given your yield goals and investment here. I can't advise trying this on every acre but with some experience you could probably uncover a means to justify harvesting 90+ bpa soybeans in October after a sprayer trip.

Oh, and I should run a budget on this... I'm pretty sure that seed rate adjustments could cover late N application costs (besides deferring rate decision until knowing exactly what soil moisture looked like.)

So that's it. My nod to our poor secondary crop. I love chatting about plant growth so drop a comment below. There's so much I left out that others have tried with good success. This is just my preferred crop plan for high yields. What is yours?

1. Start with good soil. If you haven't got any then improve it.

2. Rotate with other crops. Multiple years of corn, then cereal rye cover crop.

3. Plant early. Yield potential is established AFTER you plant and you need flowering sites.

4. Time fertility for ~20# soil nitrates prior to V3. This can be from variety of sources... no more, no less.

4. Plant very long season variety. Again, more flowering sites increase max potential.

5. Adjust population to expected lodging and shade. Tall beans never yield.

A) Lower populations where soil nitrogen is expected to be higher than desired early.

B) Lower populations in wider rows for less plant to plant competition.

C) Lower populations with longer maturity (they'll make it up)

6. No weeds allowed. Spray early and often.

6. Track soil moisture and only augment late if possible. No irrigation? Pray for rain.

7. If you have soil moisture late, top dress with N at beginning of seed fill to meet yield goals.

8. Treat pests and disease according to scouting.

9. Consider desiccant for harvest aid.

10. Harvest timely and with proper settings.

11. Sow cover crop to soak extra high N load from vibrant plants.

This is over simplified and highly opinionated. It's also proven with experience on about a zillion field observations and various trials. I left out some things that should be obvious, and also some details about things that will make this all automatic. We're working on software that will help. In the mean time, this should guide you.

The key to high yielding soybeans is having an environment that is rich for the plant's needs at each time of its life cycle. There are two primary stages. Vegetative and Reproductive. They overlap from flowering until the end of new leaf development. You want to maximize the nodes and thus flowering sites per acre based on your environment. This changes across the field and throughout your planting window. You need to adjust according to these things! Furthermore, you should augment your available nitrates to stimulate bacteria to get to work early (a little N boosts leaf surface and juices the roots for faster and greater nodulation.) But, you don't want too much N early as the bacteria get lazy. This might mean reducing your tillage and growing a high C:N cover to soak and tie up N early. Sounds funny to suggest augmenting N levels to DECREASE nitrogen levels but it's truly important. In fact, studies show too much N early can delay N fixing and ultimately crush yields. Be careful.

Once healthy, evenly spaced plants have taken off in a nitrogen balanced environment, your job is to protect them so they can develop an insanely high number of flowering sites. This means protecting their water source (soil), root development (compaction), and leaf surface (insect and disease.) With crop rotation most of that is taken care of free of charge. The planter becomes increasingly valuable as your populations become lower. You cannot skimp here. Try treating them with same affection as corn... seriously, try it. Some people are known to time their row units so they drop equally spaced soybean seeds... and raise 160+ bpa records.

Ultra long season varieties have longer vegetative periods. In fact, we have proven that the day length sensitive talk is bogus. That's right... it's garbage. Instead, focus on GDD heat units prior to flowering. After flowering the soybean marches to maturity based on the fact that there is a night and not necessarily the length of the night (can anyone say, street lamp green beans?) So, the plant sees the light switch, takes a nap and then wakes up to grab sunlight again. You should focus on selecting a variety that will march to maturity close to or even after anticipated frost given your planting date and temperature outlook. (obviously, you don't want to harvest every field after frost, but this post is talking about ultra high yield, okay!)

Soybeans grow like a cube. Their geometry is much different than corn (a cylinder). They will canopy at about the same height as their row width. This isn't exact but it's a decent rule of thumb. Given their ability to add flowering sites at an exponential rate, your exact population is highly influenced by your row width, planting date and maturity. What is the best row width? Tell me your planting date, seed variety and soil properties and I'll have an opinion.

As your tree-like soybeans sprawl out with tons of flowers and massive nodules on their roots, you'll want to know what your soil moisture profile looks like late in the season. You should have well over 100 bushel potential based on node count per plant. As such, you'll need to feed the seeds developing in all these pods! History shows that good bean years favor dry early and wet late with good soil N mineralization happening late. Soybeans require around 5# per bushel of N and can produce 60-70% from atmosphere. This means that if your soil contributes 80# (3.5% OM soil) your cover crop releases some late and you want more than 100 bpa, you're going to need an additional 50-80# N top dressed. How do you apply it and what source? That's up to you but do as little crop damage as possible and get it into the root profile. Foliars are not going to be enough.

For most of my midwest farmer buddies, the idea of spraying soybeans in October with a descecant sounds crazy. I might get made fun of... but this won't be the last. The truth is, a crazy lush, full season soybean plant is going to want to hang on and keep pumping late into the fall. It really doesn't care that you have empty grain bins. It wants more and more seed and will push the plant right up until you or mother nature say stop. That's totally okay given your yield goals and investment here. I can't advise trying this on every acre but with some experience you could probably uncover a means to justify harvesting 90+ bpa soybeans in October after a sprayer trip.

Oh, and I should run a budget on this... I'm pretty sure that seed rate adjustments could cover late N application costs (besides deferring rate decision until knowing exactly what soil moisture looked like.)

So that's it. My nod to our poor secondary crop. I love chatting about plant growth so drop a comment below. There's so much I left out that others have tried with good success. This is just my preferred crop plan for high yields. What is yours?

Why Notill Farmers Dig Precision Ag

I've been running a precision ag crop consulting and software company since 2006. Prior to that I farmed full time. Fortunate for me, my father and I practiced notill farming and utilized yield monitors and variable rate technology. For me, it was normal... but since then, I've learned that the two practices go hand in hand. Now, I'm fortunate to work with several of the best in class for both of these practices. Here are my top reasons as to why these practices tend to converge.

1. Early adoption... Both practices are relatively new in the whole scheme of farming. Leaders make decisions that result in change and these leaders are moving early.

2. Management... let's face it, full width tillage is easier... and so is doing what you did last year. Both notill and precision ag require more management. Some say they adopt one or the other just for the challenge, while others say profit motivates them. I would agree with Farm Futures survey (need to get link) that shows highest profit farmers practice and enjoy both ...and reap the profit reward for their management.

3. Speed... High profit farms tend to get more bushels in less time... both labor and machinery. This is accelerated by both techniques and multiplied when used together.

4. Timing... Time is money, and timing is priceless. Notill and cover crops emphasize timing field operations with natural environment. Alongside this is data quest to understand what is working, both NOW (in field sensor), and what happen prior (yield monitor and rate trials.)

I firmly believe the most important element to farm profitability is timing. Making hay when the sun shines is about leveraging your brain and brawn to lower risks and increase rewards. It costs almost nothing to do it at the right time versus the wrong time... and with advances in notill machinery and precision technology the cropping system as a whole is more "forgiving" on timing. What do I mean by that? A well managed notill field can support machinery traffic before tillage can be performed and then the system loses less moisture to the atmosphere and soil to erosion all while increasing equipment speed per acre... and decreasing time spent per acre. This all adds up to better timing by the farmer.

This is by no means comprehensive but were just a few things on my mind this evening. (plus, I was due for a blog post... my timing was getting behind!)

Cheers and thanks to my readers for following!

1. Early adoption... Both practices are relatively new in the whole scheme of farming. Leaders make decisions that result in change and these leaders are moving early.

2. Management... let's face it, full width tillage is easier... and so is doing what you did last year. Both notill and precision ag require more management. Some say they adopt one or the other just for the challenge, while others say profit motivates them. I would agree with Farm Futures survey (need to get link) that shows highest profit farmers practice and enjoy both ...and reap the profit reward for their management.

3. Speed... High profit farms tend to get more bushels in less time... both labor and machinery. This is accelerated by both techniques and multiplied when used together.

4. Timing... Time is money, and timing is priceless. Notill and cover crops emphasize timing field operations with natural environment. Alongside this is data quest to understand what is working, both NOW (in field sensor), and what happen prior (yield monitor and rate trials.)

I firmly believe the most important element to farm profitability is timing. Making hay when the sun shines is about leveraging your brain and brawn to lower risks and increase rewards. It costs almost nothing to do it at the right time versus the wrong time... and with advances in notill machinery and precision technology the cropping system as a whole is more "forgiving" on timing. What do I mean by that? A well managed notill field can support machinery traffic before tillage can be performed and then the system loses less moisture to the atmosphere and soil to erosion all while increasing equipment speed per acre... and decreasing time spent per acre. This all adds up to better timing by the farmer.

This is by no means comprehensive but were just a few things on my mind this evening. (plus, I was due for a blog post... my timing was getting behind!)

Cheers and thanks to my readers for following!

Tuesday, May 7, 2013

Building Rx while in the Field

I'm pretty pumped that planting is underway in Indiana. Since I can't resist sharing ideas on this blog, I thought I'd throw one out there for you all to chew on. Share it! (links are embedded so you could make it work while you are planting if so inclined!)

I’m

going to field now to test it on a 20/20.

(UPDATE: Well, the farmer was kind enough to spend three minutes and go through steps with me... the trouble is the FieldView app does not allow you to pick from the DropBox folder. I grabbed my Chromebook, connected to my iPhone hotspot and downloaded zip files. The grower then logged into his FieldView app and we uploaded the zip folder without extracting... then, synced his iPad and "bam" he had it on his 20/20. Very slick... but not yet totally doable via iPad only. Please comment if we missed something!)

I just used my iPhone to create a VR Seed map in Optmzr,

download, extract and post to Dropbox! What does this mean?

If a farmer has an iPad connected to a 20/20 they can create and

get fresh Rx while in the field. (not quite yet... see below for UPDATE.) Here is how:

2. Select

“Open With…”

3. Extract

contents into a new folder using iZip app.

4. With

iZip still open, navigate to files you want to send to Dropbox, ignoring

Nitrogen files, or vice versa with seed depending on what you are doing. (Optmzr downloads all VR applications to that field every time since they can change with the weather.)

a. Highlight

appropriate files (need .shp, .dbf and .shx)

b. Select

“Send” from iZip app and chose Dropbox as the destination (install Dropbox app on iPad if haven’t already.)

c. Select

desired folder to place files in.

5. Files

appear in DropBox.

With this complete you may “Share” the folder to customer

(or use your own FieldView if you’re a farmer) and download files to your

iPad and port rates files into your 20/20 per FieldView steps.

All of this can be done with the iPad while in the field if

you have an internet connection. And, the shapefiles are small so they move easy.

(UPDATE: Well, the farmer was kind enough to spend three minutes and go through steps with me... the trouble is the FieldView app does not allow you to pick from the DropBox folder. I grabbed my Chromebook, connected to my iPhone hotspot and downloaded zip files. The grower then logged into his FieldView app and we uploaded the zip folder without extracting... then, synced his iPad and "bam" he had it on his 20/20. Very slick... but not yet totally doable via iPad only. Please comment if we missed something!)

Friday, May 3, 2013

Why My Business Does Not Give Away Hats

If you've been a farmer for more than 3 months you have probably received a free hat from a seed company or the like. Instead of hats we give away text messages. Why? Because everyone cares about yield!

Below is the form we use on www.Optmzr.co/free.php

Try it out here, it's live!

Below is the form we use on www.Optmzr.co/free.php

Try it out here, it's live!

Wednesday, May 1, 2013

Four Monitors and a Vision

Yesterday I had the good fortune to receive a warm welcome by Kerry and Angela Knuth onto their Mead, Nebraska farm office which is a few miles from their home. In the barn lot, their 48 row corn planter was detached from the massive green tractor while others in the neighborhood planted. Angela informed me that Kerry had to run up to the John Deere dealership and would return momentarily (it turns out the several hundred thousand dollar tractor rear end had failed and was going to be replaced within the week.)

I stepped into their farm shop and through the interior door leading to the community style office work space not unlike many professional farmers. What then happened was fascinating... Angela invited me to take a seat at her work station and man the controls to her four monitor computer (yes, four... as in twice as many as two.) She inquired of our software Optmzr.co and wanted a refresher on an earlier webinar. This was fine but slightly awkward for me. I was much more interested in knowing about their farm as I had driven from Indiana to "ride in a corn planter in Nebraska" just to find they had decided not to plant given the snow in the forecast for the next day. (stay tuned for more on that later in this post.)

As we got the conversation revved up I was asked to turn and meet her nephew who oversees their web site and is encouraging her to post on their newly created blog (visit it here.). He has experience (and talent) in cinematography and production. Although his Mac Pro only had one monitor his enthusiasm for his work resonated with me as did Angela's encouragement for him to share his business card.

Shortly thereafter, Kerry arrived, back from the dealership and was rather curious as to what we were messing around with (I'm sure April 30th farm visits are not generally a welcome thing... particularly when very little planting progress has been made.)

Nonetheless, he warmed up quickly and we wound up standing in the barn yard reviewing statistics, business strategy and weather forecasting as it relates to production systems management on the farm. Bubba (given name of Terral), the main sprayer operator, joined us in the barn lot and shared a quip about telemetry systems allowing Angela to read the tractor monitor while he is in the field so "I can get an ass chewing today instead of tomorrow" afforded us some comic relief. (Angela quipped back, "you haven't had a chewing in a while!")

As if from an AB Production, the scene was back dropped by an elderly man on an open cab tractor discing up a patch of the front yard which I hoped was going to be a garden. They all laughed and said, "We'll save you from an introduction to him. He wouldn't like you anyways."

I'm a long way from home but farms across our fine nation have a lot in common... and a few of them have just enough contrast in them to create massive separation. It was my pleasure to visit and spar on tech ideas for the next few years with this farm family. May they and the rest of you have a safe and productive planting season.

Oh, and Angela, may you plant on the day with the Mayflower tree is in full bloom! (do you even have Mayflower trees in Nebraska?! ha!)

Tuesday, April 16, 2013

What do software developers have in common with farmers?

This weekend Optmzr.co is being honored at the Techpoint Mira 2013 award gala. This event is expected to draw more than 1,000 attendees, most of which will be wearing tuxedos and evening gowns to what is affectionately known as the "Oscars of Technology" for the state of Indiana. My wife and I are attending because our company's software tool, Optimizer 2.0 was nominated by some of our developers as "The Innovation of the Year" (and some other tech people considered it worthy of being a finalist... read more here.)

This gala is unlike many award ceremonies that I am used to, often featuring a cowboy comedian or a slideshow of farm scenes... instead, we'll be surrounded by tuxedos, ice sculptures and videographers. People will be tweeting and snapping pictures of each other in silly poses for their "social media strategy." All that is fine but somewhat Oscar-like from my point of view which is to say... weird.

This gala is unlike many award ceremonies that I am used to, often featuring a cowboy comedian or a slideshow of farm scenes... instead, we'll be surrounded by tuxedos, ice sculptures and videographers. People will be tweeting and snapping pictures of each other in silly poses for their "social media strategy." All that is fine but somewhat Oscar-like from my point of view which is to say... weird.However, I don't want to down play the significance of this event or the motivation of the people behind it and being recognized. There truly are some exemplary thought leaders and innovative people involved. Several companies can trace significant growth as a direct result of being honored, while other Indiana companies have gone on to successful IPO's and international significance. Indiana has a budding tech scene and celebrating these accomplishments is an important motivator for many involved... and well deserved.

So what do software developers have in common with farmers? Both start with a foggy vision of what they want to grow, and how their work might materialize. They invest significant lonely hours, pouring heart and soul into the seeds of their idea. They shepherd their vision and act as stewards of their growing project and adjust both their visions and efforts according to what is practically most urgent. Both must exercise patience and faith. They live a daily mantra of "If I seed it, someone else will add the growth." Timing is also critical for both. Too much too early, or too little, too late and failure becomes imminent and apparent to both themselves (often later) but first to the on-looker. In the end, both the farmer and the software developer hope to build a fertile environment that perpetuates healthy returns for years to come. It's not always easy or pretty, but with hard work and some good fortune (luck?) they both can enjoy the fruits of their labor and talents.

I'm going to this event to celebrate Indiana technology and the common thread of an enterprising people group. I realize we wouldn't be there without our team's hard work, or our farmer's adoption. Hopefully the others in attendance won't mind my work boots... there is still a lot to do!

Saturday, March 23, 2013

Why the Term "Prescriptions" is Dead

I started writing prescriptions when I was a teenager... and I'm no Doogie Howser.

Honestly though, why did precision ag start using the phraseology "Rx" and "Prescriptions" and "Scripts?" My theory is that the original power users of precision ag software either had a PhD or felt like they deserved a PhD for figuring out how to use the stuff.

In the coming years Variable Rate file generation will not require a PhD.

And why should they? I have farmer customers that build and download their files from their smartphones... fast and easy. I know of no other business manager that asks a "doctor" what they should do next. Rather than getting a prescription for some ill condition, most savvy business managers look to adjust plans to preempt painful conditions. As such, they are comfortable with limited knowledge and willing to accept some risk. This is quite unlike a doctor who tests, diagnoses and prescribes treatment AFTER symptoms have revealed themselves.

Certainly there is good reason to use sound statistics and mine spatial data for insights regarding trend forecasts. Every good manager needs insights and forecasts based on their actual data. There is certainly a role for consultants and suppliers to play a relationship role in helping shape parameters for the controller files, but the setup and delivery needs to be fluid and adaptable if for no other reason than the weather changed the circumstances!

So what should we call it? Let's just call it "Download file" or "Crop Plan" or "VR File" or something less suggestive and more accurate. The emphasis shouldn't be on making us some software/research demi-god but rather on the agreeable logic applied to match up with the farmer's own strategic vision for his farm.

Instead of building software that is suitable for a demi-god only, let's write software that normal humans can run. No certification required. Let's make it fast, easy and fun... and profitable for the farmer and the salesman.

Honestly though, why did precision ag start using the phraseology "Rx" and "Prescriptions" and "Scripts?" My theory is that the original power users of precision ag software either had a PhD or felt like they deserved a PhD for figuring out how to use the stuff.

In the coming years Variable Rate file generation will not require a PhD.

And why should they? I have farmer customers that build and download their files from their smartphones... fast and easy. I know of no other business manager that asks a "doctor" what they should do next. Rather than getting a prescription for some ill condition, most savvy business managers look to adjust plans to preempt painful conditions. As such, they are comfortable with limited knowledge and willing to accept some risk. This is quite unlike a doctor who tests, diagnoses and prescribes treatment AFTER symptoms have revealed themselves.

Certainly there is good reason to use sound statistics and mine spatial data for insights regarding trend forecasts. Every good manager needs insights and forecasts based on their actual data. There is certainly a role for consultants and suppliers to play a relationship role in helping shape parameters for the controller files, but the setup and delivery needs to be fluid and adaptable if for no other reason than the weather changed the circumstances!

So what should we call it? Let's just call it "Download file" or "Crop Plan" or "VR File" or something less suggestive and more accurate. The emphasis shouldn't be on making us some software/research demi-god but rather on the agreeable logic applied to match up with the farmer's own strategic vision for his farm.

Instead of building software that is suitable for a demi-god only, let's write software that normal humans can run. No certification required. Let's make it fast, easy and fun... and profitable for the farmer and the salesman.

Friday, March 15, 2013

Weld Smartphone to VR Controller

"I've been building variable rate files since before smartphones." - Old timer Precision Agronomists

Mark my words, this will be something the old timers will brag about. This week, a customer of ours downloaded variable rate shapefiles from his smartphone and transferred them to his Ag Leader monitor... through a USB cord he had laying around. Yep. It is real.

No offense to Nathan, but he doesn't have a computer science degree or anything crazy. He is like a lot of other farmers... he has determination and ingenuity. This week, he and "his precision ag guy" Travis from Case dealer, Jacobi Equipment in Columbus, IN simply got inspired to try and make this simple idea work... much like my dad or others would weld together some objects to make life easier on the farm. And after downloading an app to unzip his prescription download, he was able read the files straight from his phone into his monitor. Done. No USB thumbdrive needed.

"No more USB drives for me," said the dealer. Now he can download and install updates to customer's monitors at will. Besides that convenience, he could also simply email the customer and allow them to download their own firmware updates and install from their own phones while in the field.

When I heard what Nathan did, I started jumping around our office, doing a little dance and yelling. Sarah and Lauren think I'm crazy anyways so no big deal. I was excited because not only did I not even ask this customer to try this but I knew that he saw what www.Optmzr.co could provide him and how immediate recommendations that are updated by the weather could have an impact on what he wanted to do in the field in real time. He saw it and simply couldn't wait for us to build an app. He didn't check with his corporate attorney or ask permission from his boss. Instead, he tried it on his own and made it work. I love farmers!

The result is that while planting he can download a new rate file at his whim.

Nathan shot video of process above.

What does that mean exactly? It means that after building his best laid cropping plan (variety by field), he has a solid plan B in his shirt pocket if the weather dictates something different... What if the next field east is ready to plant but he has a planter full of wrong variety? Seem complicated? I mean, how does he retrieve Plan B when it isn't even built yet? Well, Nathan will simply pull out his smartphone while finishing planting one field, tweak variety intentions for the next field, download his files and begin planting his new prescription in the next field... using all the available weather, soil and seed and timing data at his fingertips... all done without calling, texting or paying for additional data plans or equipment!

That is farmer ingenuity at its best. Want to download the exact How-To that Nathan gave us? Make a comment and we'll trade emails! "Weld your Smartphone to Your Monitor with a USB cord."

Monday, March 4, 2013

Use Soil Tests for VR-N

What is the most important soil property for managing variable rate nitrogen? Soil organic matter (aka OM).

For dozens if not thousands of years farmers have inherently known "good soil" from "poor soil." The first and most obvious is the color and smell. Both of these sensory elements relate to the break down of organic matter... decomposing carbon material... dead plant and animal life and manure. This natural compost is biologically active even after losing the original plant shape. Microbial life is busy eating and converting material into energy and releasing nutrients that help new plant life flourish.

There is a lot of work in modern agriculture to refine variable rate nitrogen. Improving the rate and timing of nitrogen is important for improving water quality as it is managing costs and yield on the farm. As one of the single most expensive inputs on the farm, nitrogen is also high on the list for farmers to manage well. However, it is very complex given the mobility and variability within the field.

Rather than explain the entire N cycle, I would like to share and propose the use of soil test OM values to improve nitrogen rate decisions on your farm. At a minimum this approach can provide you some base guidelines for how "good" exactly is your soil. In some more complex treatments, you might also model the nitrogen mineralization from the OM based on soil moisture and temperature properties. This can empower you to tweak timing and understand plant stress at various growth stages.

We work with a farmer that has taken soil samples on 1 acre grids and uses OM to drive his VR seed and VR nitrogen rates. Still others we work with deploy ISNT or other measures. Every farm and farmer is unique so approach this with your own smallest management unit... for one, subdividing a soil type will be enough, while another will want a tighter grid or even some higher resolution soil color sensor.

A simple suggestion to step up from just the basic SSURGO soil type maps would be to subdivide your SSURGO zones for a modified grid soil test. In so doing, you take your soil test in smaller zones which better describe patterns within the field (agree or not?!) Then you would use the OM value from your soil test and assign an anticipated nitrate release through the growing season. When you build out your nitrogen budget you can then deduct this soil contribution!

Piece of cake, right?! Well, not quite... since any field with large variability in soil OM probably should also have variability in yield goals within the field. If that is the case (which is normally so), then you'll want to adjust your gross N needs before deducting soil contributions. In some cases this might even things out, but in many areas, your yield goals might be nitrogen limited because of historical compromises you've made elsewhere. What do I mean by that? Perhaps you've been shorting nitrogen rates in that "medium" textured soil because you didn't want to over do it on the poor soil? You've had enough seed and water, but ran out of N. Not good! So, is the answer applying a higher straight rate across whole field? Not if you want economics or environment to pan out well for your future!

In this way, we believe it is critical to compile ALL aspects of the soil that can effect yield and nitrogen movement. You can make significant strides in cost savings and efficiency by doing a good job creating zone specific yield goals and working backwards from that. However, the true yield gain values are wrought after understanding what of your soil can be managed to optimize performance. That is, what is most limiting? Fix it, then ask what is now most limiting. Fix it, then so and and so forth. (ever heard of Game Theory?!) When this is applied to nitrogen as it is relative to other aspects of crop growth you stand better odds of increasing yields along with improved N efficiency.

If you'd like to know how we use software to do this in our business, please visit http://www.optmzr.co/software.php#soil-test-upload

Sunday, February 24, 2013

Drive VR Seed Before Planting

This Friday we took a field trip from the office. We loaded up our GIS Tech team and a couple Agronomists and two Trailblazer and went out to the field with a laptop and Farmworks Sitemate installed with a GPS puck and drove some snowy fields. Our objective? Check out some new VR-Seed rate files.

Over the course of several years, we sometimes run into farmers that dislike our prescriptive maps. (odd, huh? but true.) Most of them are very understanding and chock it up to a learning experience to improve upon next season. However, we always take it to heart and work to make them meet their objectives. One such way is to load up a file on a laptop and do some pretend farming while the soil is frozen. This is also a great way to get our computer geeks out to the field and "feel" the changes as if they were farming it.

So how does it work? We basically just drive up and down some rows, through some low areas and basically just looking for places that might be "weird" in the map based on the current position. During this particular run we found that some of our logarithmic logic wasn't quite as smooth between SSURGO zones as it appeared on the map. We discussed how we would change the parameters in the algorithms between stops.

We visited another field with some different logic applied to it. The maps looked much better. In fact, the particular fields we traversed had both extreme hills, along with minor topographic changes. There were stark changes in soil color, and moderate variations, all within the same 200 acres. A stiff boot heel kick into the soil made checking soil color easy, as well and the driver going to what he perceived to be "a good area" and then the laptop operator stating the rate out loud.

All in all, we learned a lot about what made the algorithms work and where we needed to make adjustments (and some ideas about specifically how.) It was really cool to see the maps locate and accurately describe just slight changes in the field that you could intuitively perceive.

What tips do you have to prevent waste on your farm for the 2013 crop? Do you ever "pretend farm" as a way to help you learn?

Over the course of several years, we sometimes run into farmers that dislike our prescriptive maps. (odd, huh? but true.) Most of them are very understanding and chock it up to a learning experience to improve upon next season. However, we always take it to heart and work to make them meet their objectives. One such way is to load up a file on a laptop and do some pretend farming while the soil is frozen. This is also a great way to get our computer geeks out to the field and "feel" the changes as if they were farming it.

So how does it work? We basically just drive up and down some rows, through some low areas and basically just looking for places that might be "weird" in the map based on the current position. During this particular run we found that some of our logarithmic logic wasn't quite as smooth between SSURGO zones as it appeared on the map. We discussed how we would change the parameters in the algorithms between stops.

We visited another field with some different logic applied to it. The maps looked much better. In fact, the particular fields we traversed had both extreme hills, along with minor topographic changes. There were stark changes in soil color, and moderate variations, all within the same 200 acres. A stiff boot heel kick into the soil made checking soil color easy, as well and the driver going to what he perceived to be "a good area" and then the laptop operator stating the rate out loud.

All in all, we learned a lot about what made the algorithms work and where we needed to make adjustments (and some ideas about specifically how.) It was really cool to see the maps locate and accurately describe just slight changes in the field that you could intuitively perceive.

What tips do you have to prevent waste on your farm for the 2013 crop? Do you ever "pretend farm" as a way to help you learn?

Wednesday, February 13, 2013

Improve VR-Seed by Subdividing SSURGO data by Slope

Farmers often use SSURGO soil type data to assign seed

rates. Their main assumption relates to

water holding capacity and organic matter as these macro soil attributes greatly influence ability to support higher populations. However there are some limitations to this public data set. They blame various things,

mostly related to resolution (aka "the darn lines are in the wrong place.")

When frustrated, farmers sometimes ask for normalized historic

yield maps to improve or replace SSURGO data.

However, when we’ve done this we often encounter resistance when they

finally get to the field. Why? Because it ends up assigning low rates to

“good soil” that they have tiled or otherwise improved. Often times the yield data has problems, like

switching varieties, missing data in middle of a field or only a few years of

“good data.” We can over exaggerate underlying soils rates but all this adds up to

conceptually liking the idea but practically avoiding it given lots of poor quality yield data. Can you say, tail wagging the dog?!

A long time goal of ours was to better describe predicted

soil moisture using slope. Despite the ease at which one can look and

perceive slope from an elevation map it is quite challenging to mathematically

capture it in most existing GIS software.

Well, we finally accomplished just that… both max-grade and position on

hill… top or bottom portion of the hill itself.

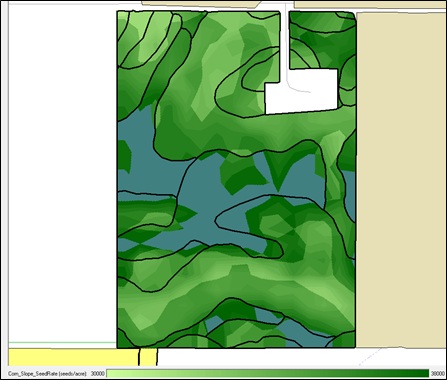

Above is a corn yield map from drought stricken

2012 field. As you can clearly see, the

yields don’t change exactly with the specific soil type zones change. However, it's decent, albeit, not perfect. Where "off", is that because they are wrong or because a B

slope soil type is simply too great a generalization for this application? Said another way, B slope simply means gently

rolling, but doesn’t say “this is a hill top.”

Sometimes it is, but often it has hill tops and valleys both, which

yield differently. Given the tabular data quality of the SSURGO

maps (and their ease of retrieval,) we’re not convinced we should abandon them just yet. Instead, how about we improve it?

Below is a VR seed map for corn with original SSURGO map overlaid. You can see how the slope

extends the normal zone rates across various soil types. To accomplish this we started with a VR-Seed

map based on soil type and then used some logarithmic math to distribute based

on a proprietary slope algorithm. The

lower position in the hill (at same slope) gets more seed than does the same

slope toward the hill top. In fact, the

math effectively describes the concave or convex proprieties of all “hills and

valleys” at the given 100 ft square resolution.

Additionally, this VR-Seed file means that the farmer won’t

have those hard polygon transitions while traversing the field. In fact, the rates will gradually shift

higher or lower as he transitions between soils and varying slopes. Same soil type but in a valley? No problem… we’ll drop more seed. Same soil but on the top of the hill? No problem, we are dialing back. This elevation influenced data is able to be

accomplished even with WAAS data because of the relative nature of slope

position and 100 ft horizontal resolution. The ultimate result is a refined seed rate without

a crop consultant even visiting the field.

The final map is our proposed VR-Seed map for soybeans. As you might notice we invert the rates to

lower population to prevent lodging in the appropriate positions in valley of high OM soil types. At this point, we believe a good

farmer could “trump” these maps with his knowledge about drainage, fertility or

other oddities not represented in these two data sets that make his soils

different than the underlying SSURGO properties. (or, subdivide his SSURGO using smart zone soil sampling first and then apply this slope logic afterward!)

Monday, February 4, 2013

My first ever re-blog Post

If you've ever wondered about staying power, technology and convergence of mind, guts and glory on the farm... look no further than my friend Brian Scott, aka @TheFarmersLife. Nice post about Super Bowl commercial that incorporates his family.

http://thefarmerslife.wordpress.com/2013/02/04/ram-trucks-wins-superbowl-with-so-god-made-a-farmer/

I'd say more but his post says enough.

Daryl

http://thefarmerslife.wordpress.com/2013/02/04/ram-trucks-wins-superbowl-with-so-god-made-a-farmer/

I'd say more but his post says enough.

Daryl

Monday, January 21, 2013

Maybe we need to start a call center?

"Help, I'm addicted to big corporations and am sick of it." That'd be the mantra of my new call center. We'd take inbound calls from distressed farmers who's production practices are being prescribed by the same corporations that engineer their seed.

Now if this doesn't sound like a cataclysmic opener to an organic leftist tribal chant, I'm not sure what does... however, I must say that I'm starting to lose respect for the "rugged independent" nature of the American farmer. Heck, even in Ancient Rome they used to hold up the farmer as a necessary occupation in society that was able to voice their opinion without threat of customers leaving them.

I've come to learn and respect a few of the "agvocates" still out there. The AgChat Foundation is delving out some pretty nice dialogue and blogs via Twitter, Facebook and more. These organizations appear to be led by some fantastic people who have a grounded approach. My concern however isn't so much about the education of the non-ag community, but rather the education of the farmers themselves.

For the last hundred years or so, our land grant universities have provided a third party resource of replicated trials to improve farm practices and advanced cropping systems. As the industrialization of ag has evolved so has their funding, and now the only research that gets done is somewhat tainted by the requests set out by the funding grants, often deployed by the same multi-national corporations.

Trade publications are also a source of information for many farmers... particularly favorable to the advertisers therein. No doubt these folks have to make a living through ad space but do they really have large enough budgets to advance the science of farming? No, their role is to give a comprehensive presentation of what the goings on are in ag are at the present moment.

Some 15 or so years ago many people thought farmers themselves would develop more on-farm research protocol through the use of precision ag technologies. Farmers were expected to lay out large block trials and then scout and record yield data... even process the data in the winter for new insights. The trouble with this is the same in other commodity industries like mining or t-shirt manufacturing... they simply cannot leverage the R&D necessary to convert the investments in significant research into value on the other end of the production chain. It is simply in their best interest to adopt early and deploy cost saving measures widely and quickly.

The trouble with zero R&D and early adoption being the best business model is that as we enter the information and communication age of agriculture the rate of adoption will actually accelerate and the margin for competitive error will erode. As land changes hands the production systems go into fewer hands and become necessarily closer to their vertical suppliers. Perhaps that is just natural but I'm just not certain I trust the stock market and government to oversee the stewardship of our land.

The good news is that I've met a growing segment of medium/large growers that have built both cash reserves as well as fixed equity and are turning toward technology to garner greater insights into the actual needs of their farm. With faster information flow these growers are leveraging their own management of their systems and becoming better managers of water, soil health, sunlight and other basics that are very, very low cost to acquire compared to their long term benefit to their business. As landowners recognize the separation in their systems approach they are acquiring land under favorable terms and setting themselves up with a multiplicity of suppliers with more equal yoking.

If anyone happens to read this article and feels compelled to join me in the call center, please let me know. I'm not much for sob stories but would appreciate helping a few people use their brains.

Now if this doesn't sound like a cataclysmic opener to an organic leftist tribal chant, I'm not sure what does... however, I must say that I'm starting to lose respect for the "rugged independent" nature of the American farmer. Heck, even in Ancient Rome they used to hold up the farmer as a necessary occupation in society that was able to voice their opinion without threat of customers leaving them.

I've come to learn and respect a few of the "agvocates" still out there. The AgChat Foundation is delving out some pretty nice dialogue and blogs via Twitter, Facebook and more. These organizations appear to be led by some fantastic people who have a grounded approach. My concern however isn't so much about the education of the non-ag community, but rather the education of the farmers themselves.

For the last hundred years or so, our land grant universities have provided a third party resource of replicated trials to improve farm practices and advanced cropping systems. As the industrialization of ag has evolved so has their funding, and now the only research that gets done is somewhat tainted by the requests set out by the funding grants, often deployed by the same multi-national corporations.

Trade publications are also a source of information for many farmers... particularly favorable to the advertisers therein. No doubt these folks have to make a living through ad space but do they really have large enough budgets to advance the science of farming? No, their role is to give a comprehensive presentation of what the goings on are in ag are at the present moment.

Some 15 or so years ago many people thought farmers themselves would develop more on-farm research protocol through the use of precision ag technologies. Farmers were expected to lay out large block trials and then scout and record yield data... even process the data in the winter for new insights. The trouble with this is the same in other commodity industries like mining or t-shirt manufacturing... they simply cannot leverage the R&D necessary to convert the investments in significant research into value on the other end of the production chain. It is simply in their best interest to adopt early and deploy cost saving measures widely and quickly.

The trouble with zero R&D and early adoption being the best business model is that as we enter the information and communication age of agriculture the rate of adoption will actually accelerate and the margin for competitive error will erode. As land changes hands the production systems go into fewer hands and become necessarily closer to their vertical suppliers. Perhaps that is just natural but I'm just not certain I trust the stock market and government to oversee the stewardship of our land.

The good news is that I've met a growing segment of medium/large growers that have built both cash reserves as well as fixed equity and are turning toward technology to garner greater insights into the actual needs of their farm. With faster information flow these growers are leveraging their own management of their systems and becoming better managers of water, soil health, sunlight and other basics that are very, very low cost to acquire compared to their long term benefit to their business. As landowners recognize the separation in their systems approach they are acquiring land under favorable terms and setting themselves up with a multiplicity of suppliers with more equal yoking.

If anyone happens to read this article and feels compelled to join me in the call center, please let me know. I'm not much for sob stories but would appreciate helping a few people use their brains.

Thursday, January 17, 2013

Using Precision Ag to Save Money or Yield More?

A recent publication from PrecisionAg.com http://www.precisionag.com/article/32148/soybean-research-summary-downloadable-pdf-now-available inquired of the reasons farmers use precision ag. The main thing that stood out to me besides row crop farmers love of machinery, is the fact that there are really only two reasons to adopt any type of increased precision in your farming system.

1. Cost savings - these normally amount to reduced input application. GPS soil testing and VR fertilizer application are used to avoid over application of P & K. Most early adopters of variable rate seeding have done so to reduce total units of seed purchased, either through guidance, row shut off or reduced populations on their thinner soil types. From my point of view these motives are fine but are somewhat short sighted and not very inspiring, particularly for the high yield kings of the neighborhood that know the best way to reduce ALL input costs is to raise higher yields.

2. Increased yield - Fewer people, but still a significant amount, responded that their main reason for adopting variable rate was yield gains. Of all aspects the stand out was variable rate seeding with nearly 60% indicating yield gains were main reason for adoption. Still, guidance, row shut off, and other implement controls were touted as a means to increase yield by improving placement. This is unfortunate but very revealing of the state of the industry. Variety to soil matching or variable rate seeding was not touted.

What do we need to change this? Please comment!

1. Cost savings - these normally amount to reduced input application. GPS soil testing and VR fertilizer application are used to avoid over application of P & K. Most early adopters of variable rate seeding have done so to reduce total units of seed purchased, either through guidance, row shut off or reduced populations on their thinner soil types. From my point of view these motives are fine but are somewhat short sighted and not very inspiring, particularly for the high yield kings of the neighborhood that know the best way to reduce ALL input costs is to raise higher yields.

2. Increased yield - Fewer people, but still a significant amount, responded that their main reason for adopting variable rate was yield gains. Of all aspects the stand out was variable rate seeding with nearly 60% indicating yield gains were main reason for adoption. Still, guidance, row shut off, and other implement controls were touted as a means to increase yield by improving placement. This is unfortunate but very revealing of the state of the industry. Variety to soil matching or variable rate seeding was not touted.

What do we need to change this? Please comment!

Subscribe to:

Posts (Atom)